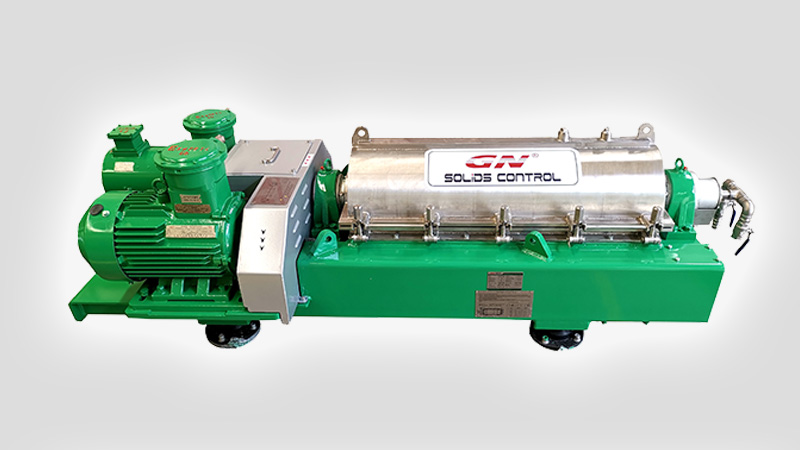

A solid-liquid two-phase decanter centrifuge, also known as a decanter or a decanter centrifuge, is a type of industrial separation equipment used for separating solid particles from a liquid mixture. It operates based on the principle of sedimentation and centrifugal force.

Here’s how a solid-liquid two-phase decanter centrifuge typically works:

Feed Introduction: The mixture of solid and liquid is introduced into the decanter centrifuge through a feed pipe or inlet.

Separation Zone: Inside the decanter, there is a rotating bowl that houses a cylindrical rotor. The mixture is fed into the separation zone, where the centrifugal force generated by the high-speed rotation of the bowl causes the solid particles to settle on the bowl wall, forming a cake layer.

Clarification: The clarified liquid phase, also known as the centrate or effluent, flows towards the center of the bowl due to the centrifugal force. It is then collected and discharged through specific outlets.

Solid Discharge: As the solid cake layer accumulates on the bowl wall, it is continuously pushed towards the conical end of the bowl by the rotating screw conveyor (also called the scroll). The screw conveyor transports the solid cake towards the discharge ports, where it is removed from the centrifuge.

The key advantages of using a solid-liquid two-phase decanter centrifuge include efficient solid-liquid separation, continuous operation, and the ability to handle large volumes of feed material. These centrifuges find applications in various industries, such as wastewater treatment, chemical processing, food and beverage, pharmaceuticals, and mining, among others.

It’s important to note that specific details of a decanter centrifuge, such as its capacity, rotational speed, and design, may vary depending on the manufacturer and intended application. If you require more detailed information or have specific inquiries about a solid-liquid two-phase decanter centrifuge, I recommend consulting with manufacturers or suppliers who specialize in this equipment