GN Company’s Oil Sludge Treatment System received great attention among Middle East clients, especially for countries have big amount of long-term oil sludge pool waiting for treatment. Generally these pools have big area and the pools are located in different places of these countries. The situation in each pool is different, and some pools have high content of crude oil, while other pools might have high content of solids. The clients would like to recover clean oil from the oily sludge, and discharge the water to local area under suitable condition, and as well the solids in the oily sludge. The pool is far from each other, and clients ask the machine shall be installed in container or on skid, which can be convenient to move around different job sites.

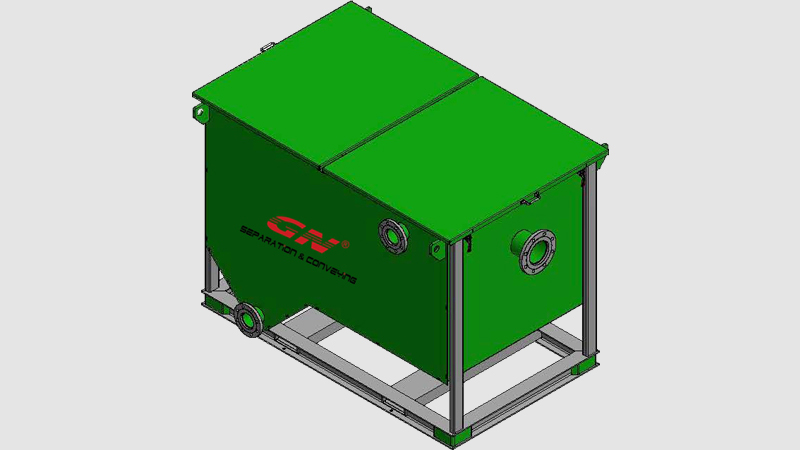

GN Company supplies One Stop Turnkey Solution for oil sludge treatment.

Please find the video from linkage as below.

https://www.youtube.com/watch?v=hXrzm5J_k1A

This system can be widely used for crude oil tank sludge, refinery plant waste oil sludge, and drilling waste oil sludge, etc.

GN Technical Team suggests solids content in the sludge feeding into GN System less 20%. And if the solids content is too high, clients can mix with water in the first step. Heating the oily sludge to 60~70 degree can also GN System to get better performance.

This system includes Industrial Vibrating Screen, 2-Phase/3-Phase Decanter Centrifuge, 3-Phase Disc Stack Separator, and supporting accessories, such as tank, pipeline, heating devices, polymer dosing system, etc.

Industrial Vibrating Screen is used to separate coarse solids from oily sludge (bigger than 100um).

Decanter Centrifuge is mainly used for solids/liquid separation (less than 20um).

Disc Stack Separator is used to purify the liquid phase discharged from Decanter Centrifuge.

Welcome to contact GN Sales Managers, and they would offer detailed solution based on clients’ requirement.

Best & Regards,

Kevin Liu

Regional Manager

GN Separation & Conveying

Hebei GN Separation & Conveying Equipment Co.,Ltd

Tel: +86-316-5276988/9

Mob (WhatsApp/Wechat): +86-15810901775

Email: Kevin@gnseparation.com

GN China: www.gnseparation.com (Langfang/Beijing)

GN USA: www.gnsolidsamerica.com (Houston, Texas)

GN Russia: www.gnseparation.ru (Moscow City)