GN separation, a professional manufacturer in the filed of solid-liquid separation, has successfully compeleted the assembly of a oil sludge system, it will be sent to South America Client shortly.

The oil sludge treatment system would utilize a decanter centrifuge and some related equipment to efficiently separate the oil, water, and solids contained in oily sludge and waste streams. This is a common and effective technology for treating oil sludge and separating the valuable oil component from the water and solids.

GN separation can manage to design the whole system base on the mateiral, areas and climate on site to meet customer’s need.

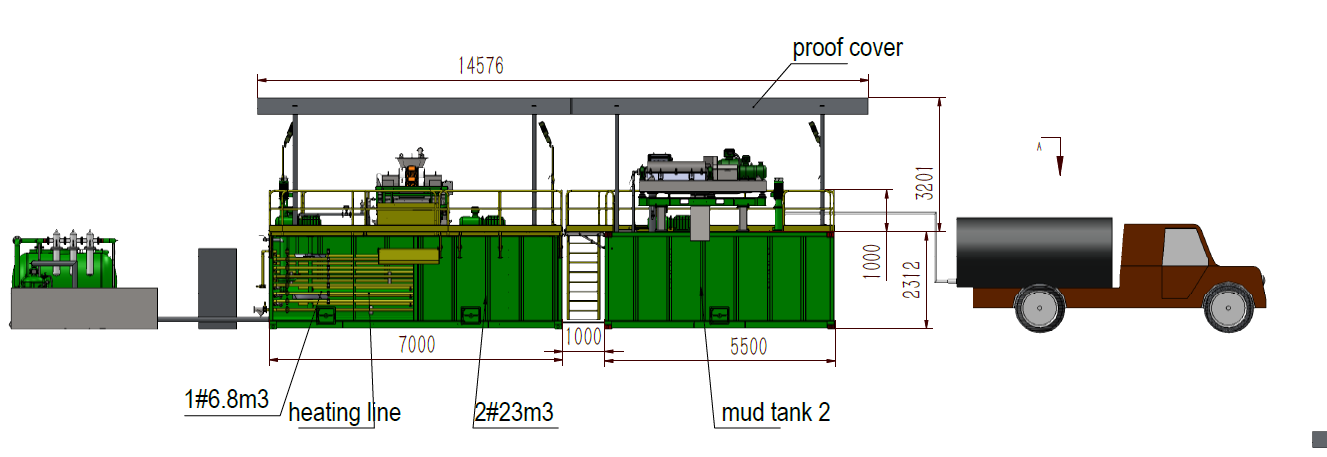

The system comprise serverl modular design as below

- Oil sludge transferring Module

Sludge’s begins at the Material Handling Module where GN’s proprietary solids vacuum pump comes into play. This fully pneumatic, easy-to-maintain unit efficiently transports the sludge from its storage area to the screening module, ensuring a seamless and safe transfer process.

- Screening Module

GN vibration screen will work on it, These powerful machines carefully separate larger particles and debris from the sludge, greatly reducing the workload of downstream fine separation equipment. This preliminary step is essential to prepare the sludge for more complex treatment processes, thereby increasing the efficiency of the entire system.

- Fine solid-liquid separation module

The core of the system is the decanter centrifuge, This advanced technology is tailored to the client’s specific requirements, enabling precise solid-liquid or liquid-liquid-solid separation.

By reducing the volume of hazardous waste, recovering valuable resources, and minimizing environmental impact, GN’s oil sludge treatment system not only addresses immediate challenges but also contributes to a greener, more resilient future for the industry.

For more question, pls feel free to contact GN.