What is Hydro Excavation?

Hydro Excavation is now popular in North America for excavating soil by High Pressurized Water. Then an air conveyance or vacuum is used to transfer the mixture of water, soil, large size trash and some other materials into a debris tank. This Hydro Excavation allows for a non-destructive to excavate soil and locate underground utilities.

How to deal with the Hydro Excavation Waste Slurry Treatment?

GN Solids Control provides One Stop, Turn Key Solution to recover water and discharge the soil suitable for environment. The process diagram is as below.

1. Waste Collecting and Washing Module – the waste slurry is delivered to site via the hydro truck and then discharged to a large size collecting hopper at which bottom there are valves to discharge the slurry onto a coarse screen for large size trash separation.

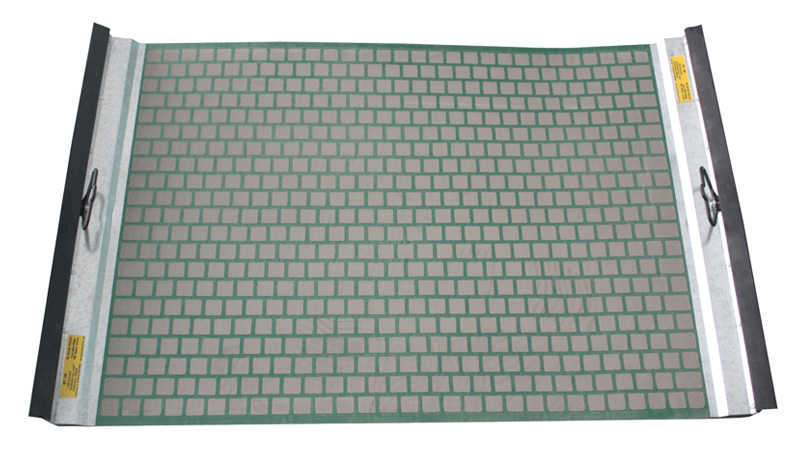

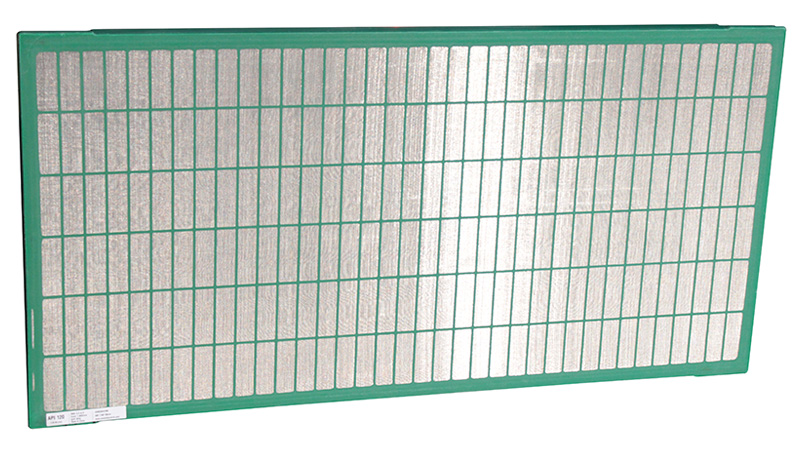

The liquid with fine particles is collected in the tank located under the coarse screen. The liquid is then pumped to GN high G force drying shaker for finer solids separation. Here the operator can also use pressure flushing device to wash the slurry. GN shaker is fixed with composite frame shaker screen for longer working time and better performance.

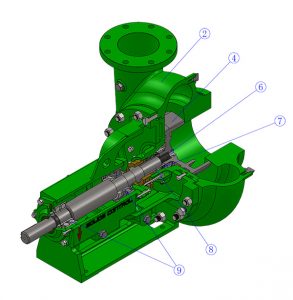

2. Fine Solids Hydro cycling Separation Module – GN desilter with hydro cyclone manifold is fixed on a washing tank for further separation of the fine solids. The under shaker of the desilter is same model with GN drying shaker for easy maintenance. The hydro cyclone is using centrifugal force and gravity to separate the liquid and solids. The slurry is pumped into the cyclone with high speed for effectively separation process.

3. Dewatering Centrifuge Module – in this hydro excavation waste slurry treatment system, a decanter centrifuge (bowl diameter is 9 inch, 220mm) is used to remove the ultra-fine solids in the slurry. A chemical dosing system can be connected to the dewatering centrifuge to increase the efficiency of the separation.

Welcome to contact us for more detailed information.

Kevin Liu

kevin@gnseparation.com

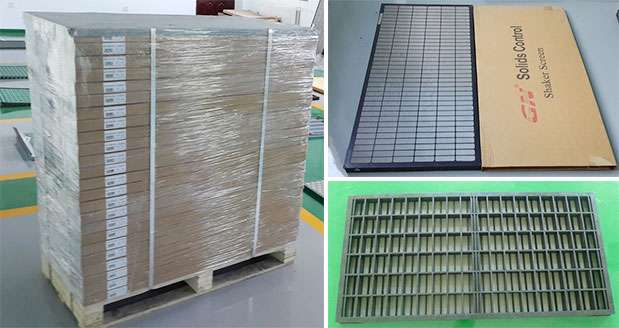

GN Screen Type

GN Screen Type