Вертикальная сушилка и центрифуга для африканской компании по утилизации отходов

В последние годы проблема управления отходами становится все более актуальной во всем мире, в том числе и в Африке. Африканская компания по управлению отходами активно ищет эффективные решения для обработки отходов, и в этом контексте вертикальный сушильный агрегат для вырезок и центrifужный узел представляют собой важное оборудование.

Вертикальный сушильный агрегат для вырезок предназначенв основном используется для сушки различных видов вырезок, которые образуются в процессе обработки материалов. Он имеет множество преимуществ. Во – первых, его конструкция позволяет обеспечивать равномерную сушку вырезок. В процессе работы горячий воздух или другой сушильный агент подается в вертикальный сушильный агрегат, и вырезки движутся в вертикальной плоскости, что обеспечивает хорошую контакт между вырезками и сушильным агентом, в результате чего вода или другие влаги быстро испаряются. Во – вторых, этот агрегат обладает высокой производительностью. Благодаря своей компактной конструкции и эффективной системе циркуляции воздуха он может обрабатывать большое количество вырезок за короткое время, что значительноПовышение производительности.

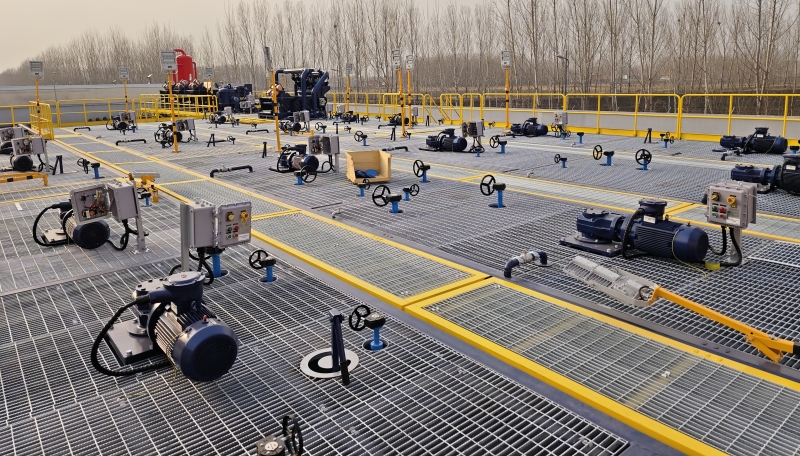

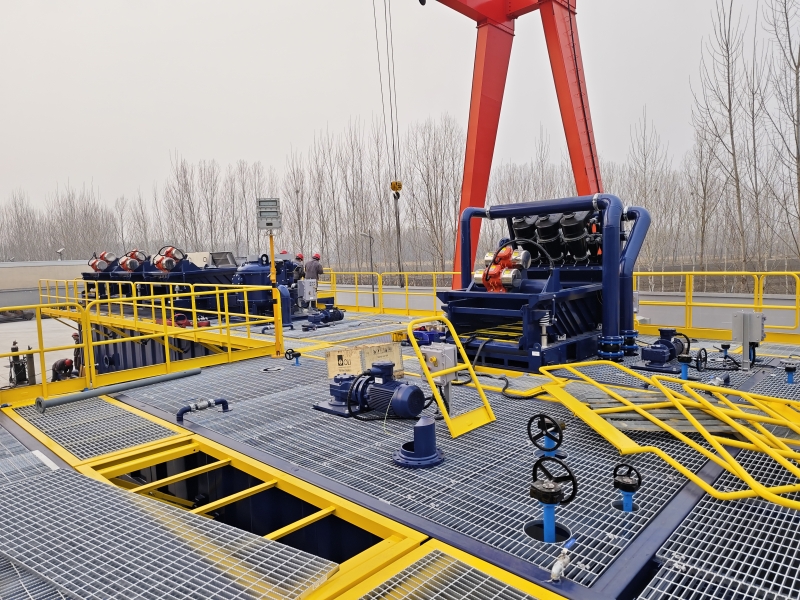

Центrifужный узел также plays a crucial role в системе управления отходами. Он используется для разделения твердых и жидких фаз в отходах. Когда отходы поступают в центrifужный узел, благодаря быстро вращению центрифуги твердые частицы отходов под воздействием центрифugalной силы отделяются от жидкой фазы. Это позволяет эффективныйное разделение и утилизацию твердых и жидких отходов. Например, в нефтегазовой промышленности центrifужный узел может быть использован для обработки буровых отходов, где твердые частицы могут быть утилизированы или отправлены на дальнейшую обработку, а жидкая фаза может быть повторно использована в буровых работах, чтовносить вклад в снижения затраты и уменьшения воздействия на окружающую среду.

Для африканской компании по управлению отходами использование вертикального сушильного агрегата для вырезок и центrifужного узла имеет huge significance. С одной стороны, это позволяет увеличивать масштаб the efficiency of waste treatment. Традиционные методы обработки отходов могут быть длительными и неэффективными, а с применением этих современных устройств можно значительно свернуть время обработки и увеличивать масштаб the quality of treated waste. С другой стороны, этовносить вклад в environmental protection. Через effective drying и separation of waste, сокращается the volume of waste that needs to be disposed of, и вредные вещества в отходах могут быть лучше controlled, что reduces the pollution to the environment.

Кроме того, использование таких устройств также может bring economic benefits. Сокращение затраты на обработку отходов и повышение эффективности использования ресурсов мог утувеличивать масштаб the profitability of the waste management company. И в долгосрочный, с улучшением ситуации с управлением отходами в Африке, компания сможет expand its business scope и establish a good reputation in the market, что привлечет Больше клиентов и партнеров.

В conclusion, вертикальный сушильный агрегат для вырезок и центrifужный узел являются важными составляющими для африканской компании по управлению отходами. Они могут provide effective solutions для обработки отходов, contribute to environmental protection, bring economic benefits и promote the development of the waste management industry in Africa. С развитием технологий и increasing demand for waste management, эти устройства будут постоянное совершенствование и играть более важную роль в будущем.

Система очистки\|Вибросито бурового раствора,Ситогидроциклонная установка-GN Solids Control – GN Solids Russia