There is a batch of Shaker Shakers ready for shipment to Indian’s work site for drilling project.

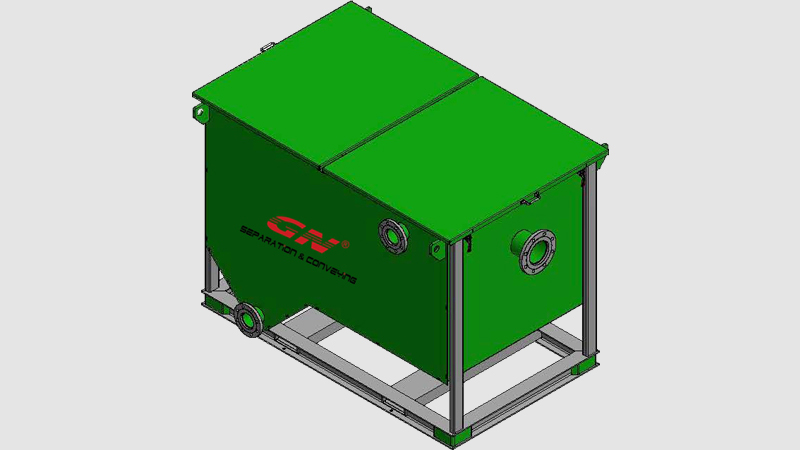

GN Company is a professional manufacturer of Solid/Liquid Separation, Solid/Liquid/Liquid Separation Equipment for 12 years, including Decanter Centrifuge, Disc Separator, Shale Shaker, Desander, Desilter, Mud Cleaner, etc.

India is a huge market, with steady sales amount increase, and GN Managing Board pays big attention on developing India market.

GN Company would attend the IFAT 2019 exhibition in Mumbai.

Date: October 16th~18th, 2019.

Address: BOMBAY EXHIBITION CENTER, MUMBAI, India.

Booth No.: D41A, Hall 1

We would show products as follow,

- Decanter Centrifuge – Solids-liquid separation, solids dewatering, waste water concentrate, Edible oil production, mining tailing dewatering, other industrial separation

- Sludge Solid Vacuum Pump – High solid content sludge transfer, oily waste sludge transfer, solid powder transfer, animal waste transfer

- Centrifugal Pump – Drilling mud transfer, light slurry transfer

Welcome to contact GN Sales Managers for technical specifications and offers.

We would attend IFAT Exhibition in Germany, dated on May 4th~8th, 2020, with booth No. 104-b, Hall A1

Best & Regards,

Kevin Liu

Regional Manager

GN Separation & Conveying

Hebei GN Separation & Conveying Equipment Co.,Ltd

Tel:+86-316-5276988/9 Fax:+86-315-5276990

Mob(WhatsApp/Wechat): +86-15810901775

Email: kevin@gnseparation.com

Web: http://www.gnseparation.com

Address: No. 1 Zhongxun Road Dachang Chaobai River Industry Zone, Langfang, Hebei, China (Close to Beijing Int. Airport)