Since the new regulations for China oilfield

environment is issued, GN solids control has

provided over 25 sets of drilling waste management system for their water based

drilling fluids.

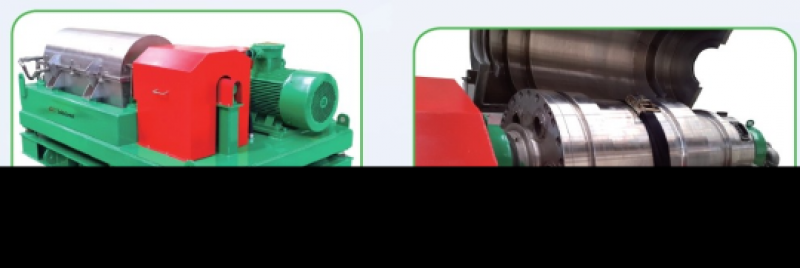

The main features of GN drilling cuttings treatment

system including:

1 Modular design: vertical

cuttings dryer, high G dryer, decanter centrifuge are all set on top of the

telescopic skid as a separate module, each module can be used separately when

the actual situation is required by the rigsite, and they can be used together

for best performance.

2 Less cost, good effect, the cuttings discharged from

the vertical cuttings dryer is dry as powder, which can be disposal directly or

used for construction industry without damage of the environment. Before using

GN drilling waste management equipments, the drilling company use the truck to

ship the drilling cuttings from the mud pit to a waste management factory, the

liquid waste spray out and they get a lot of complains from the farmers.

3 To recycle/reuse the clean fluids and less the

drilling cost. The working principal of GN drilling cuttings treatment system

is mechanical separation, without any chemicals additives. The clean fluids

discharged from

decanter centrifuge can be used for preparing the drilling fluids. Unlike

other supplier’s proposal, we do not add chemicals during the process, it will

not damage the configuration of the original drilling fluids, it can save a lot

of cost for the drilling fluids and less the waste treatment cost.

4 The high-G dryer is used to less the fine solids

content of the drilling fluids before feeding to the decanter centrifuge, the

unique design can make the centrifuge working longer time with less wear on the

screw impeller.

5 The drilling

waste management system for water based drilling fluids can be also used

for your oil based cuttings treatment, you do not have buy another unit , this

modular waste management system can be used for both of your applications.

/o:p�qpW"