Shale Shaker Screens are widely used for Shale Shakers and Mud Cleaners.

Generally the screens shall be changed every 300~400 working hours, but that depends on the detailed project information. It is a Big Cost for the drilling companies/contractors or Solids Control Companies to purchase Shale Shaker Screens, especially when they buy the Original Screens from those reputable famous brands.

GN Solids Control understands the cost-effective shale shaker screens are very important for the solids control equipment.

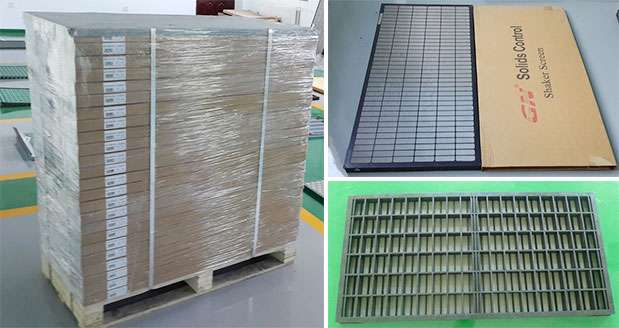

So GN keeps researching and developing the best technology for manufacturing the Top Quality shaker screens for our clients. Now one of the major business of GN Solids Control is Shale Shaker Screen, and GN is able to manufacture around 8000 PCs of shaker screens every month. With our distribution network and cost-effective products, GN Shale Shaker Screens are popular around the world.

GN Screen Type

GN Screen Type

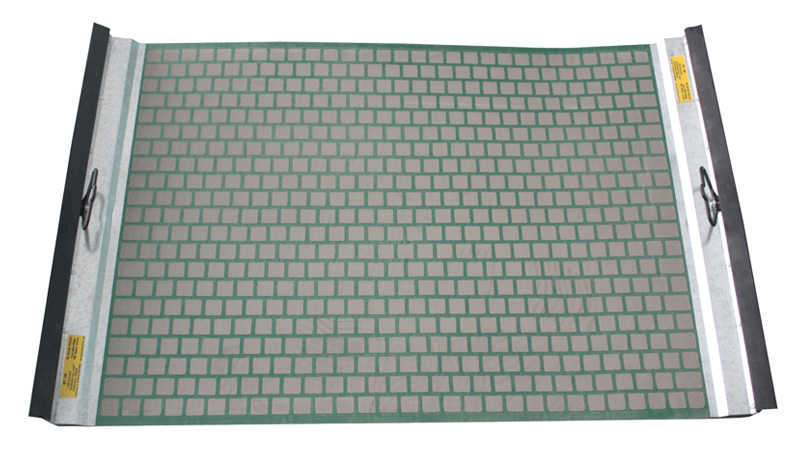

Hook strip flat screen

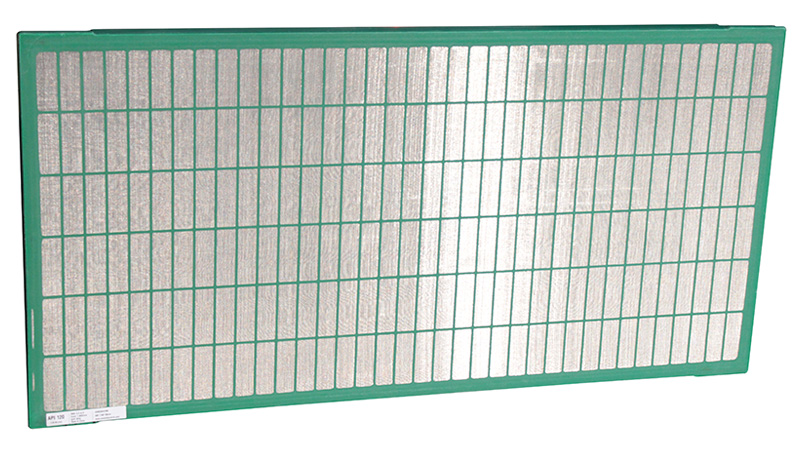

Steel frame screen

Composite frame screen

Pyramid screen

Hook strip soft screen

And more…

GN Replacement Screen

Original Screen for GN Solids Control shaker

Replacement screen for Derrick Shaker

Replacement Shaker Screen for MI-Swaco Shaker

Replacement Screen for NOV Brandt Shaker

And more……

What API Size Shaker Screen available from GN

| D 100 Separation(Micron) | API Screen Number |

|---|---|

| >1850.0 TO 2180.0 | API 10 |

| >780.0 TO 925.0 | API 20 |

| > 462.5 TO 550.0 | API 35 |

| > 390.0 TO 462.5 | API 40 |

| > 275.0 TO 327.5 | API 50 |

| > 231.0 TO 275.0 | API 60 |

| > 196.0 TO 231.0 | API 70 |

| > 165.0 TO 196.0 | API 80 |

| > 137.5 TO 165.0 | API 100 |

| > 116.5 TO 137.5 | API 120 |

| > 98.0 TO 116.5 | API 140 |

| > 82.5 TO 98.0 | API 170 |

| > 69.0 TO 82.5 | API 200 |

| > 58.0 TO 69.0 | API 230 |

| > 49.0 TO 58.0 | API 270 |

| > 41.5 TO 49.0 | API 325 |

Hereby GN would like to emphasis that we have big stocking in the North American and China Mainland, the clients can receive the screens from us within two months, wherever they are.

Welcome to contact us if you need sample, test report or RFQ.