GN

Solids Control is a very famous company working on solids control and drilling waste management systems for many years. Many famous clients are

using GN equipments as well as GN solids control turnkey systems.

With

the establishment of GN Solids America and GN Solids Russia, GN Solids Control

is providing its good quality products to over 60 countries.

Now

GN can design and manufacture shale shakers with linear motion, vacuum

degassers to

eliminate gas in the mud or drilling fluids, desilters and desanders for finer

solids separation, cuttings dryers for OBM, WBM or SBM drying work, decanter

centrifuges for 2 or 3 microns solids separation etc. GN has the ability to manufacture

various types mud tanks, mud plant, square tanks, v type tanks etc. All these

tanks can be put into use with excellent qualities.

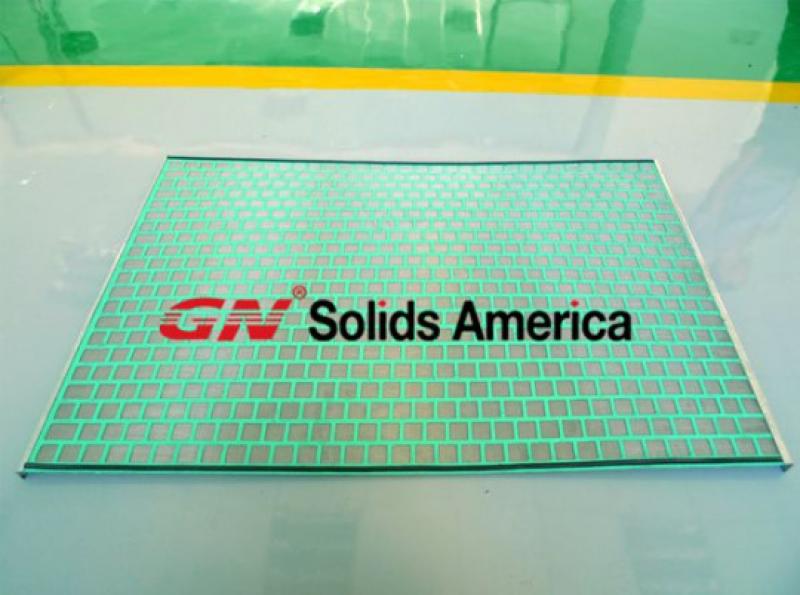

As

you might know, GN Solids Control is manufacturing many different kinds of shale shaker screens. Many famous brands shaker screens can be

replaced by GN shake screens.

We

all know that Derrick, Brant, Fluids System etc are famous for their shakers

and screens, GN is also one famous manufacturer to offer different types of

shaker screens. For GN shakers, GN has one type of shale shaker which is 594,

this shaker are using the same size shaker screens as Mongoose. And now GN

Solids America is

keeping certain storage in GN Houston warehouse. Whenever our clients have the

needs of shaker screens, GN can send our shaker screens directly to our

customers’ worksite in a short period.

And

GN Solids America is keep making storage plans for regular clients, we can add

it into our storage plan if you can tell us the API no. or mesh no.

GN

also keeps some other equipments in Houston warehouse besides these shaker

screens. Equipments such as shale shakers, mud cleaners and decanter

centrifuges are stored in GN TX warehouse, welcome to give us a phone call if

you are interested.