GN Conveying & Separation Company attended IE EXPO CHINA 2019 dated on April 15~17th, 2019, at Shanghai New International Expo Center.

This is Asian’s leading environmental show, with covering all the high potential markets in environmental area as below,

Water/Waste Water and Sewage Treatment

Waste Management

Site Remediation

Air Pollution Control and Air Purification

GN Company is a professional manufacturer of Waste Water & Oil Sludge Treatment System (removing Solids and Water, and collecting Clean Oil for reuse) for 11 years, including,

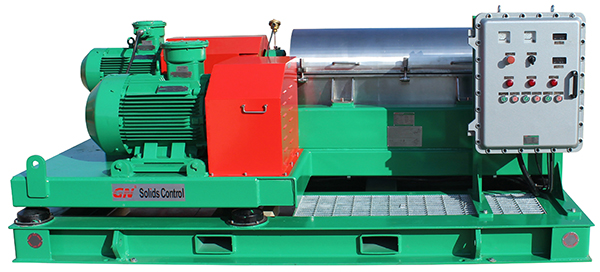

Decanter Centrifuge (widely used for Solid Liquid Separation, Mud/Sludge De-watering)

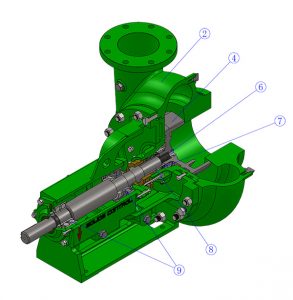

Solids/Sludge Vacuum Pump (widely used for Sludge, Solids, Slurry Transferring & Conveying)

Oil Water Separator

Tank Cleaning System

Mud Agitator

Screw Conveyor, etc.

Now GN Company has three factories, about one hour from the Beijing International Airport by car, with more than 100,000 square meters totally, and supplying equipment to about 76 countries.

Besides GN Company, all the other Chinese main environmental protection engineering companies and service companies also participated in the exhibition.

GN showed three devices for this exhibition as below,

1. Decanter Centrifuge (GNLW224E & GNLW363)

2. Sludge/Solids Vacuum Pump (GNSP-40 & GNSP-20)

3. Centrifugal Sand Pump

Welcome to contact GN Company for more Technical Specifications & Working Video of our equipment.

It is acceptable to post sample to our factories for testing and checking.