Recently GN Company finished production for 8 sets of Mud Recycling Plants, and would arrange final delivery to client’s work site.

GN Mud Recycling Plant is widely used for Bored Piling, TBM, HDD (trenchless), and water well drilling etc., with working capability ranges from 50~3000m3/h.

The Mud Recycling Plant mainly includes Double Mud Shaker, Desander/Desilter, and Centrifugal Pump.

Mud Shaker is used to remove big size of Solids from the Slurry.

Desander/Desilter is used to recollecting Mud for reuse.

Centrifugal Pump is used to pump slurry to Mud Shaker.

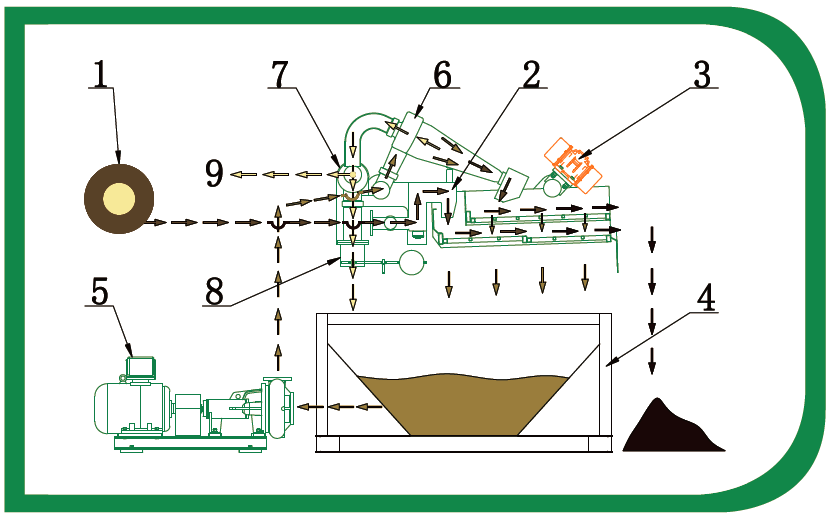

GN Mud Recycling Plant Working Procedure as below,

- Feeding mud to Shale Shaker from the mud pit. The mud would be feed onto the bottom layer screen of shale shaker (3) through buffer box(2), then the coarse particles would be separated out, while the mud would flow to mud storage tank (4) through the bottom layer screen of shale shaker(3).

- The centrifugal pump (5) sucks mud from the mud storage tank (4), and feeds to desander/desilter cone (6) with pressure used for centrifugal separation, the solids/sand would be discharged onto the upper shaker (3) from the outlet nipple of the desander/desilter cone, and fine solid would be separated out. (The screens of Upper and bottom would be different, and the Upper screen’s mesh would be higher)

- The mud passed the upper shaker screen would return back to mud storage tank (4), while the clean mud would enter into intermediary tank (7) through desander/desilter cone overflow pipe. The mud in the intermediary tank (7) would go out through outlet pipe (9) or go back to mud storage tank (4) depends on the fluid level in the recycling tank.

- In the mud circulation process, there is a fluids level float switch (8) between intermediary tank (7) and mud storage tank (4), it can balance the fluids level in the mud storage tank (4). When mud level is low in the mud storage tank (4), the overflow from the desander would enter into mud storage tank (4) through the intermediary tank (7). When the mud level is too high in the mud storage tank (4), the mud would overflow to the intermediary tank (7) and go out from the outlet pipe (9).

Welcome to contact GN Company for more Technical Specifications and Working Videos from sites.