It is mostly used design by

current that can fit several of shale shakers that

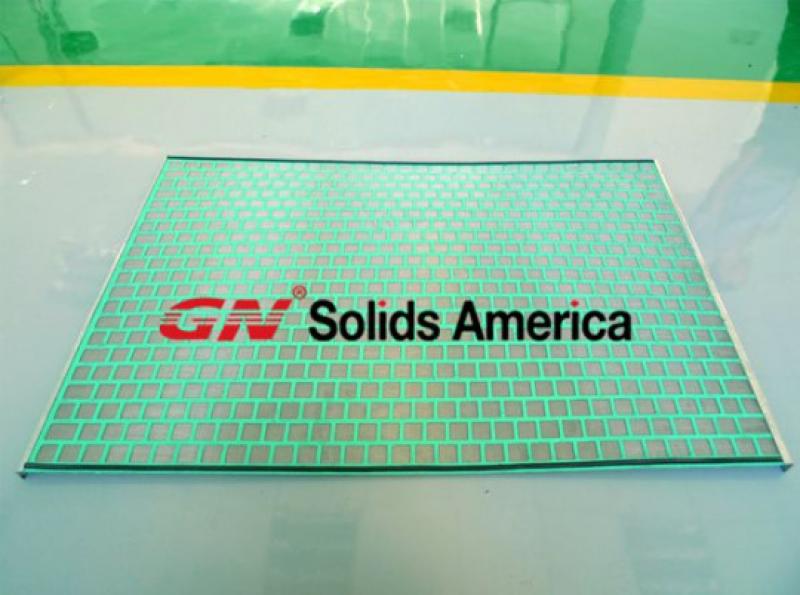

coordinate with the design concept. It is made with multiple layers of stainless

steel wire clothes together to a steel support plank. The characteristic of this type of shale

shaker screen are list below:

l

It contains different meshes on wire

cloth in the screen. The sizes of the

holes that support the plank contain different mesh as well. The support plank size also is different as

well. Combine it all will get area that

is effective on condition to bearing enough liquid flow force.

l

The thicker wires cloth contain less

mesh at the lower bottom of the screen together with support plank so it can

added strength of the whole screen to extend usage life.

l

The wire cloth is divided into many

small surface grid of steel support plank which can hold the excessive

expansion to make it last as long as possible.

Corrugate-design

shaker screen

With demand of larger and larger treating capacity

of the drilling fluid but without building larger shale shaker, the corrugate

design screen was appear in 1990s to increase the treating surface and to fit

current use shale shaker.

Corrugate design screen has large effective area, and drilling fluid

is handled in high-efficiency by using it.

This kind of sieving screen has design characteristics as follows:

l

Every wire cloth in the

sieving screen has different meshes, and accurate collocation can make the

screen have better liquid treated effect.

l

Stainless steel wire cloth is made

it like corrugate, and closely holds metal support plank together. The

effective area can added up to 125% of the flat screen with the same specification

and the size, so as to improve the quality and treating amount of drilling

fluid and increase the production.

Related Arciels: