Shale shaker is a type of very common

drilling mud solids control in all kinds of drilling projects. As a leading

manufacturer of solids control equipment, GN could provide the shale

shaker and other mud recycling equipment for oil gas

drilling, horizontal directional drilling, water well drilling, tunneling and

piling projects.

The capacities of GN’s shale shaker are

200GPM, 500GPM and 600GPM under the mud condition of density 1.2g per cubic

centimeter, viscosity 45s measured by Marsh funnel viscosimeter and screen of

API 40.

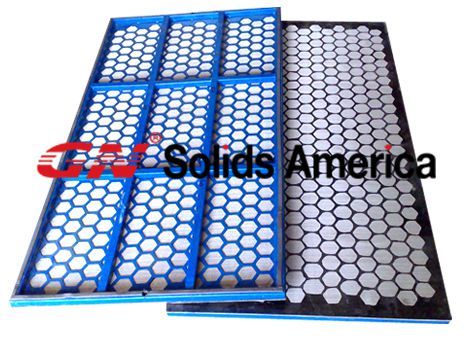

GN Solids Control has a 4-panel screens

shale shaker which is the largest model in GN’s shale shaker product line. This

model could be used at the oil rig site for primary solids control. At the

consideration of easy operation and maintenance as well as the widely accepted

treating capacity, GN made the model of GNZS594E-HB shale shaker to fully

meet the market request.

So, what are the advantages of this model?

Or we say what the features are?

1. Simple structure design of the shaker

deck, the operator could observe the work performance easily. The added extra

horizontal square steel strips at both sides of the deck make the deck much stronger.

2. The 2 vibrators located vertically with

the beam makes there is a longer connecting face which could distribute the G

force uniformly to the whole shaker deck.

3. Hidden design of the lead screw beneath

the shaker deck makes it available to adjust the shaker deck angle while the

shaker is running. The operator only need a ratchet wrench to adjust the deck

angle from one side of the lead screw, the other side would be adjusted at the

same time.

4. To ensure the better sealing

performance, the screen frame was installed a type embedded rubber sealing.

This rubber sealing will not be taken off with the exception of manually

disassembling.

5. Wedge blocks are used to fasten the

screen panels is also a popular method. This makes the exchanging of the screen

easier.

6. Sometimes the shale shaker could be used

as a under shaker of the mud cleaner unit. All GN’s shale shaker will have the

pre cut installation holes to install the cyclone frame. Which means GN’s

cyclone frame for mud cleaner is removable. All cyclone frame, no matter what

capacity, the installation location would be the same.

7. By changing hopper feeder, GN’s 4-panel

shale shaker could be used as a drying shaker for waste cutting management. The

G force is up to 8.

No hesitate to contact GN Solids Control

for a quote of GNZS594, especially the client from the America, as this model

is on a promotion status.