Few days before, GN’s

waste management equipment with regard to 3 rigs passed the particular

commissioning and started running inside Nigeria. Total 33 products equipment

were involved such as waste cuttings drying gear, ultra fine solids parting

equipment and transferring products. The pictures was taken through our

commissioning engineer whenever completion of the installation as well as

commissioning.

The client is one of the major drilling contractors in Nigeria, this is already

the 3rd purchase from this clients. Before this particular project, the client

order ten units waste decanter

centrifuge and 1 complete mud plant system from GN Solids Control.

Below back links to the other 2 projects intended for reference:

1 . Liquid Mud Plant System for Photography equipment Drilling

2 . Ten models GN Decanter Centrifuge regarding Africa Drilling Company

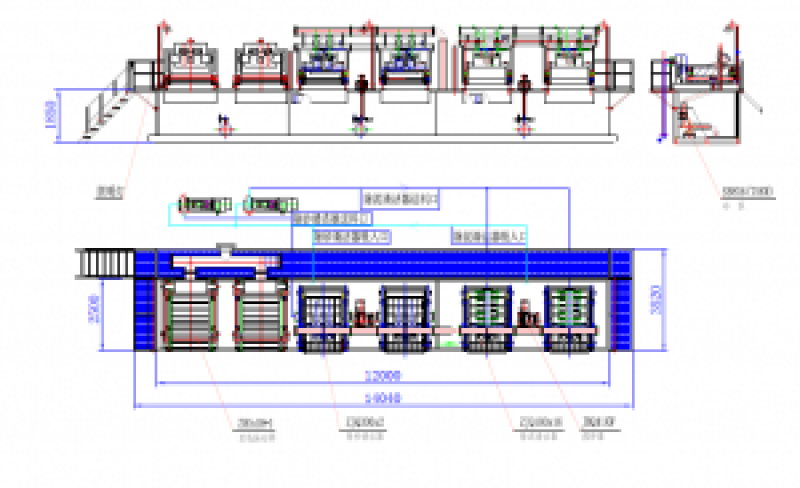

All these 33 units equipment are usually listed as below:

three or more set vertical

cuttings dryer which is main drying devices for waste cuttings, with all

the max. speed up to twelve hundred RPM, the G pressure could be up to 750.

some sets high speed VFD decanter centrifuges would meet the client’s different

requests on surgery speed and waste ailments.

Total 9 unit twist pumps, with 6 of those for feeding the aura discharged out

from the vertical cuttings dryer to decanter centrifuges, while the other 3

model for flushing to clean typically the cuttings dryer.

15 established screw conveyors are located about site accordingly for switching

the drilling waste into the dryer unit and accumulating the solids discharged

in the dryer and centrifuge.

In accordance with the feedback from the client, immediately after several

orders of GN’s equipment, they are very more comfortable with the performance.

This time, they will replaced all the equipment at a USA brand that pricing a

little high by using GN’s equipment with good feedback on both the cost and

performance.

GN nowadays has developed a series of tools especially for drilling waste

management also including the dewatering system and solidification unit. When any

request aroused, simply feel free to contact with us.