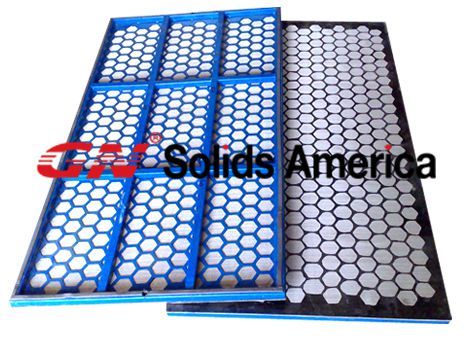

Within the solids control industry, shaker is the primary solids control unit, and shaker screen is a vital put on part for shale shaker. GN use the advanced technology to produce a number of brand shaker screens. Being an API and ISO licensed company, GN offers from API 20 to API 400 shaker screen.

Top quality and Flexibility Test

GN screens are fabricated in an array of API dimensions to make sure maximum solids control efficiency no matter the formations drilled. Our high-strength and strengthened material frames and stainless steel sieve are lighter and much more durable than usual shaker screen. What results is operational existence that’s nearly double those of other screens available on the market.

GN use constant observation, adjusted test liquids, Dry sieve testing procedure and periodic sampling testing to represent each API sieve class. GN regularly takes shaker screen to check percent elongation, ductility, wire count and tensile strength so assure each shaker screen qualtiy

Although we check carefully each shaker screen, couples of clients still complain the shaker screen blocked. You will find some reason by which make the shaker screen clogged

– How big solids is near to the dimension of opening sieve

2. Drilling liquids/mud is that contains an excessive amount of moisture

3. Particle/solids have static cling throughout the separation process

4. vibrating mesh wire through too thick

5 . The form of huge solids is flaky

6. some thicker kinds of mine screen, pass design is uncommon

Note: the contaminants/solids are essentially irregular shape, therefore the reasons of block are also different. To be able to better prevent screen clogged filter while watching products, perform some analysis and judgment before we decide the shaker screen. When you wish to filter fine contaminants or consists of more mud, water will probably cause blockage from the primary factors sieve. Hence the requirement for moisture testing contaminants, once the water is more than 5%, the requirement for blocking particulate drying out When water is more than 8% use wet sieving. Screening performing and the other reasonable regulation mesh tension can also be a highly effective measure to effectively prevent inserting sieve.